Dhumucyada ugu cimri dheer waxay ku xiran yihiin deegaanka iyo sifooyinka alaabta ee isticmaalka. Noocyada rim ee soo socdaa waxay muujinayaan adkeysiga kala duwan xaaladaha kala duwan:

1. Biraha birta ah

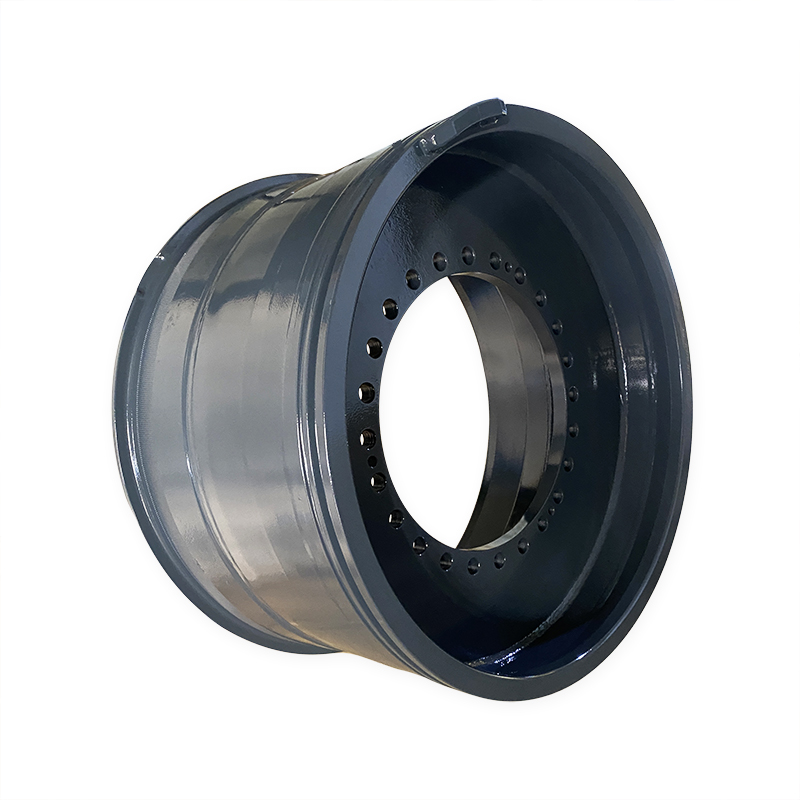

Waaritaanka: Biraha birta ah waa mid ka mid ah noocyada ugu cimri dheer ee riimyada, gaar ahaan marka ay la kulmaan saameyn xad dhaaf ah ama culeysyo culus. Aad bay ugu adkaysan karaan saamaynta waxayna u adkeysan karaan saamaynta iyagoon si fudud u dillaacin ama u jabin.

Xaaladaha lagu dabaqi karo: Ku habboon bay'ada qallafsan, baabuurta jidadka ka baxsan, baabuurta culculus, iyo mashiinnada dhismaha. Gaar ahaan ku habboon meelaha xaaladaha adag sida miinooyinka iyo goobaha dhismaha.

Dayactirka: Haddii birta birta ah ay leexdaan, badanaa waxaa lagu sixi karaa qalab dayactir fudud iyada oo aan la beddelin.

Soo koobid: Biraha birta ah ayaa ah doorashada ugu cimri dheer, gaar ahaan ku habboon culeysyada culus iyo xaaladaha adag ee waddooyinka sababtoo ah awooddooda sare iyo cimri dhererkooda.

2. Dhuxul aluminium alwaax ah oo la been abuuray

Waarta: Dareemaha daawaha aluminiumka ee la been-abuuray waxay leeyihiin xoog iyo adkeysi ka sarreeya rimyada daawaha aluminiumka ee caadiga ah. Habka been abuurka ayaa ka dhigaya kuwa cufan, saameyn badan u adkaysta, oo fudud.

Xaaladaha lagu dabaqi karo: Ku habboon baabuurta waxqabadka sare leh, SUV-yada, iyo codsiyada u baahan khafiifin. Waxay si fiican ugu shaqeeyaan wadista magaalooyinka iyo xaaladaha waddooyinka.

Dayactirka: Marka cidhifka aluminium ee been abuurka ah uu dhaawacmo, way adag tahay in la dayactiro oo badiyaa waxay u baahan tahay in la beddelo.

Soo koobid: Dhuxulo aluminium aluminium ah oo la been abuuray ayaa gaadha isku dheelitir wanaagsan oo u dhexeeya xoogga iyo iftiinka waana kuwo aad u waara oo aluminium ah.

3. Magnesium Alloy Rimyada

Joogteynta: Biraha aluminiumka daawaha ah waa kuwo aad u fudud, laakiin ma aha kuwo xooggan oo u adkaysta sida birta ama aluminiumka aluminium ee la been abuurtay. Waxay ku habboon yihiin munaasabadaha halkaas oo waxqabadka halkii adkeysi la raadin lahaa.

Xaaladaha lagu dabaqi karo: Inta badan waxaa loo isticmaalaa tartanka iyo baabuurta ciyaaraha ee waxqabadka sare leh, oo aan ku habboonayn wadista maalinlaha ah ama jawi adag.

Dib-u-dayactirka: Baakadaha daawaha ee Magnesiumku waa kuwo jilicsan, oo marka ay waxyeelloobaan, dayactirku aad ayuu u dhib badan yahay oo badanaa wuxuu u baahan yahay in la beddelo.

Soo koobid: Inkasta oo iftiinka, muraayadaha aluminiumka magnesium aysan u adkeysinayn sida birta ama aluminium been abuur ah, waxayna ku habboon yihiin tartanka ama munaasabadaha ciyaaraha ee leh shuruudo fudud oo sarreeya.

4. Kaarboon fiyuusyada kaarboon

Joogteynta: Fiber-fiber kaarboon waa kuwo aad u fudud, laakiin waxay leeyihiin adayg liidata oo si fudud ayay u dhaawacdaa saameyntu, taas oo ku habboon codsiyada u baahan iftiin xad dhaaf ah iyo waxqabad sare.

Xaaladaha lagu dabaqi karo: Tartanka ugu sarreeya ama baabuurta ciyaaraha ee waxqabadka aadka u sarreeya, oo badanaa lagu isticmaalo jidka.

Dayactirka: Marka uu dhaawacmo, xuubka fiber-ka kaarboonku waa wax aan suurtagal ahayn in la dayactiro oo badanaa waxay u baahan yihiin in si buuxda loo beddelo.

Soo koobid: Fiber-fiber Carbon waxay aad ugu fiican yihiin khafiifinta xad dhaafka ah, laakiin kuma habboona bay'ada u baahan adkaysi sare.

Sidaa darteed, biraha birta ah ayaa ah kuwa ugu cimri dheer waxayna si gaar ah ugu habboon yihiin jawiga shaqada ee culus (sida miinooyinka, goobaha dhismaha, iwm.) kuwaas oo u baahan iska caabin sare oo saameyn leh iyo awoodda culeyska.

Dabaqyada alwaaxyada aluminium ee la been-abuuray ayaa aad u waara oo leh waxqabad heersare ah. Waxay leeyihiin dheelitirnaan wanaagsan oo u dhexeeya cimri dhererka iyo miisaanka fudud waxayna ku habboon yihiin baabuurta waxqabadka sare leh iyo wadista maalinlaha ah.

Haddii adkeysiga ay tahay tixgelinta koowaad, gaar ahaan deegaannada adag, birta birta ayaa ah doorashada ugu fiican. Haddii waxqabadka iyo adkeysiga labadaba loo baahan yahay, muraayadaha aluminium ee la been abuurtay ayaa ah doorashada ugu habboon.

Doorashada cirifka saxda ah ma aha oo kaliya kor u qaadida hufnaanta shaqada ee gaariga, laakiin sidoo kale waxay kordhisaa nolosha adeegga taayirrada iyo qalabka. Tusaale ahaan,17.00-35/3.5 xajmiyada ay u isticmaalaan baabuurta waaweyn ee iska rogida baabuurta macdanta

Tignoolajiyadayadu aad bay ugu bislaadeen wax soo saarka xadhkaha goosadka ee adag. Kuwa soo socda waa qaar ka mid ah cabbirrada aan soo saari karno.

| Gaadhi iska rogo ah oo adag | 15.00-35 | Gaadhi iska rogo ah oo adag | 29.00-57 |

| Gaadhi iska rogo ah oo adag | 17.00-35 | Gaadhi iska rogo ah oo adag | 32.00-57 |

| Gaadhi iska rogo ah oo adag | 19.50-49 | Gaadhi iska rogo ah oo adag | 41.00-63 |

| Gaadhi iska rogo ah oo adag | 24.00-51 | Gaadhi iska rogo ah oo adag | 44.00-63 |

| Gaadhi iska rogo ah oo adag | 40.00-51 |

Maadaama deegaanka macdan qodista uu inta badan yahay mid adag oo ay ku jiraan dhul kakan sida godadka, dhagxaanta, dhoobada, jiirarka dhaadheer, iwm, doorashada wareegyada saxda ah ee cabbirka weyn oo lagu daray taayirada saxda ah waxay kordhin kartaa nadiifinta dhulka ee gaariga, kor u qaadida socodka gaariga. , ka caawi inay si habsami leh uga gudbaan caqabadaha ama dhulka aan sinnayn, oo hagaajiyaan xasilloonida. Intaa waxaa dheer, baabuurta macdan qodista (sida kuwa waaweyn ee macdanta iyo xamuulka) waxay u baahan yihiin inay qaadaan culaysyo aad u culus, badanaa tan ama xitaa boqolaal tan oo macdan ama xamuul ah. Xirmooyinka birta ee waaweyn waxaa lagu qalabeyn karaa culeysyo waaweyn, waxay bixiyaan aag la xiriiro culeyska weyn iyo qaadista awoodda, si siman u qaybisa culeysyada culus iyo yareynta dhaawaca taayirka.

Sidee loo doortaa birta birta ah ee saxda ah?

Doorashada birta birta ah ee saxda ah waxay u baahan tahay tixgelin dhamaystiran oo ku saabsan nooca baabuurka, isticmaalka deegaanka iyo baahiyaha gaarka ah. Kuwa soo socda waa dhowr shuruudood oo xulashada muhiimka ah iyo tillaabooyin:

1. Faham nooca iyo ujeedada gaadhiga

Gawaarida kala duwan iyo xaaladaha codsiga waxay leeyihiin shuruudo kala duwan oo loogu talagalay geesaha. Baabuurta macdanta, qalabka dhismaha, baabuurta waaweyn iyo kuwa ka baxsan wadada waxay inta badan u baahan yihiin bir adag oo adag, halka baabuurta rakaabka ah ama baabuurta fudud ay tixgelin karaan miisaanka iyo muuqaalka giraanta.

Mashiinnada culus iyo baabuurta macdanta: waxay u baahan yihiin dhumucyo, bir ka xoog badan oo u adkeysan kara culeyska sare iyo xaaladaha shaqo ee daran.

Gawaarida caadiga ah ama kuwa ka baxsan wadada: Waxaa laga yaabaa inaad u baahato gees ka dhufanaya dheelitirka u dhexeeya xoogga iyo miisaanka.

2. Dooro cabbirka saxda ah iyadoo loo eegayo tilmaamaha taayirrada

Cabbirka cirifka: Hubi in cabbirka (dhexroorka iyo ballaca) ee cidhifku uu la mid yahay taayirka. Dhexroorka cirifka ku haboon ayaa inta badan lagu calaamadeeyaa darbiga taayirka, sida "17", taas oo muujinaysa in loo baahan yahay 17-inch. Ballaca taayirka iyo cidhifka ayaa sidoo kale u baahan inay iswaafaqaan si loo xaqiijiyo badbaadada wadista iyo waxqabadka.

Xulashada ballaca: Baaxadda cidhifku waa in ay caadi ahaan ka yara yaraataa ballaca taayirka si loo hubiyo in taayirka si adag loogu ururin karo cidhifka iyada oo la ilaalinayo cadaadiska hawada iyo xasilloonida habboon.

3. Hubi awoodda rarka ee cirifka

Qiimaynta Load: Awoodda rarka ee birta birta ah ayaa aad muhiim u ah, gaar ahaan baabuurta culus. Markaad dooranayso, hubso in awoodda culeyska ee cirifka uu u adkeysan karo wadarta miisaanka gaariga iyo culeyskiisa ugu badan marka si buuxda loo raro. Awoodda culeyska ee cirifka sida caadiga ah waxaa laga heli karaa sifooyinka soo saaraha.

Shuruudaha rarka: Haddii baabuurku u baahan yahay inuu si joogto ah u raro walxaha culus ama uu ku safro dhul qallafsan, waa lagama maarmaan in la doorto birta birta ah ee leh qiimeeynta culeyska sare si looga fogaado daal ama dhaawac degdeg ah.

4. Tixgeli ka-goynta cirifka

Offset (qiimaha ET): Offset waxa loola jeedaa masaafada u dhaxaysa dusha sare ee korka iyo xariiqda cidhifka. Dakhliga saxda ah wuxuu hubinayaa in taayirka uu si fiican ula shaqeeyo nidaamka ka joojinta gaariga. Wax ka dhimis badan oo togan ayaa laga yaabaa in ay keento in taayirka uu hoos u dhaco, taas oo saamaynaysa isteerinka iyo hakinta, halka aad u badan oo diidmo ah ay keeni karto in taayirka uu aad u soo baxo, kordhinta culayska qaybaha ganaaxa.

Shuruudaha qeexida baabuurka: Dooro cirifka saxda ah iyadoo loo eegayo cabbirrada lagu taliyey ee ka-dhaafka ah ee ay bixiso soo saaraha baabuurka si looga fogaado maaraynta ama dhibaatooyinka xidhashada taayirka.

5. Iska caabin daxalka iyo daaweynta daahan

Biraha birta ah waxay u nugul yihiin miridhku marka ay soo gaadhaan bay'adaha dibadda muddo dheer, sidaas darteed waa muhiim in la doorto muraayado leh dahaarka wanaagsan ee ka hortagga. Gawaarida macdanta iyo dhismaha waxay u baahan yihiin ilaalin heer sare ah oo ilaalinta daxalka.

Xulashada dahaarka: Galvanizing, daahan budada ah ama dahaarka kale ee ka-hortagga miridhku waxay si weyn u wanaajin karaan caabbinta daxalka ee cirifka, gaar ahaan meelaha qoyan, dhoobada iyo boodhka ah.

6. Fiiro gaar ah u yeelo habka wax soo saarka iyo tayada muraayadaha

Habka wax-soo-saarka: Dooro biraha birta ah ee lagu soo saaray alxanka tayada sare leh iyo hababka samaynta si loo hubiyo awooddooda qaabdhismeed iyo adkeysigooda. Diirarka leh farshaxanimada liidata waxay yeelan karaan dhibaatooyin sida alxanka dabacsan iyo cilladaha alaabta, kuwaas oo si fudud u horseedi kara dhaawac.

Shahaadada iyo heerarka: Hubi in darafyadu ay buuxiyaan heerarka tayada ee khuseeya iyo shahaadooyinka (sida ISO, JIS ama SAE), kuwaas oo hubin kara badbaadada iyo isku halaynta rimiyadaha inta lagu jiro habka naqshadaynta iyo wax soo saarka.

7. Ka fiirso culayska darafyada

In kasta oo biraha birta ahi ay guud ahaan ka culus yihiin geesaha aluminium, geesaha birta ee kala duwan ayaa iyaguna miisaan ahaan ku kala duwanaan kara. Baabuurta u baahan in ay si joogto ah u socdaan, birta birta ah ee khafiifka ah waxay hoos u dhigi kartaa miisaanka baabuurka, waxay hagaajin kartaa waxtarka shidaalka, waxayna hagaajin kartaa maaraynta.

8. Fiiro gaar ah u yeelo is waafajinta agabka

Habka bolt Hub: Hubi in tirada iyo habaynta godadka boodhka ee cidhifka ay la siman yihiin xudunta gaadhiga. Qaabka boodhka (sida 4×100, 5×114.3) waa in uu ahaado mid la jaanqaadi kara darfaha asalka ah ee baabuurka si loo hubiyo rakibid badbaado leh.

Cabbirka daloolka dhexe: Daloolka dhexe ee birta birta ah waa in si sax ah loogu wanaajiyaa xuddunta taayirrada baabuurka si looga fogaado qallooc ku yimaadda geesaha ama khataraha badbaadada dabacsanaan awgeed.

9. Miisaaniyadda iyo kharashka dayactirka

Biraha birta ah ayaa guud ahaan ka raqiisan darafyada laga sameeyay maaddooyinka kale, laakiin qiimuhu wuu kala duwanaan doonaa iyadoo ku xiran tayada iyo daaweynta ka hortagga daxalka. Dooro bir tayo sare leh oo raagaya, inkasta oo qiimaha bilowga ahi uu yara sarreyn karo, laakiin kharashka dayactirku wuu yaraan doonaa isticmaalka muddada dheer.

Markaad dooranayso birta birta ah ee saxda ah, marka hore hubi in cabbirka cirifka, awoodda rarka iyo kabitaanka ay daboolayaan baahida baabuurka, oo ay leeyihiin ilaalin daxaleed oo wanaagsan iyo habka wax soo saarka. Haddii baabuurka loo isticmaalo hawlo culus ama deegaan qallafsan, waarta iyo awoodda culayska badan ayaa ah arrimaha mudnaanta leh; Baabuurta caadiga ah ee waddada ka baxsan ama kuwa xamuulka qaada, waxaa loo baahan yahay dheellitirka u dhexeeya xoogga iyo miisaanka.

Waxa aanu nahay nashqadaynta shaagaga kabaxsan wadada Shiinaha ee ugu horeeya, iyo khabiir hormood u ah aduunka oo ku takhasusay nashqadeynta qaybaha rim ka iyo wax soo saarka. Dhammaan alaabooyinka waxaa loo qaabeeyey oo loo soo saaray si waafaqsan heerarka tayada ugu sarreeya, waxaanan leenahay in ka badan 20 sano oo waayo-aragnimo ah wax soo saarka wheel. Waxaan si weyn ugu lug lahayn mishiinada injineernimada, cidhifyada baabuurta macdanta, geesaha forklift, geesaha warshadaha, geesaha beeraha iyo qalabyada kale ee rim iyo taayirada. Waxaan nahay alaab-qeybiyaha asalka ah ee Shiinaha ee noocyada caanka ah sida Volvo, Caterpillar, Liebherr, iyo John Deere.

Waxaan leenahay koox cilmi baaris iyo horumarin oo ka kooban injineero sare iyo khubaro farsamo, diiradda saaraya cilmi-baarista iyo adeegsiga tignoolajiyada cusub, iyo ilaalinta booska hormuudka ah ee warshadaha. Waxaan sameynay nidaam adeeg iibka ka dib oo dhameystiran, anagoo bixinayna taageero farsamo oo hufan iyo waqti ku habboon iyo dayactirka iibka ka dib si loo hubiyo in macaamiishu ay helaan khibrad siman inta lagu jiro isticmaalka. Haddii aad qabtid wax dhib ah iyo su'aalo u baahan in lagala tashado, waad nala soo xiriiri kartaa!

Kuwa soo socda waa cabbirrada kala duwan ee rims ee shirkadeena ay u soo saari karto meelo kala duwan:

Cabbirrada mishiinnada injineernimada: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 10.00-25, 11.25-25, 12.00-25, 20-13.00-25, 13.00 25, 19.50-25, 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 13.00-33

Cabbirrada macdanta: 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 28.00-33, 16.00-.30-.0. 49 , 24.00-51, 40.00-51, 29.00-57, 32.00-57, 41.00-63, 44.00-63,

Cabbirrada Forklift waa: 3.00-8, 4.33-8, 4.00-9, 6.00-9, 5.00-10, 6.50-10, 5.00-12, 8.00-12, 4.50-15, 5.50-15. 15, 8.00-15, 9.75-15, 11.00-15, 11.25-25, 13.00-25, 13.00-33,

Cabbirka Gawaarida Warshadaha waa: 7.00-20, 7.50-20, 8.00-20, 10.00x15, 10.00x15, 8.25x16.5, 16.5, 16x15, 13x15, 13x15, 13x15 .5, 9x15.3, 9x18, 11x18, 13x24, 14x24, DW14x24, DW15x24, DW16x26, DW25x26, W14x28 , DW15x28, DW25x28

Cabbirrada mashiinnada beeraha waa: 5.00x16, 5.5x16, 6.00-16, 9x15.3, 8LBx15, 10LBx15, 13x15.5, 8.25x16.5, 9.75x16.5, 9x18, 18x18 W18,18x18W W7x20, W11x20, W10x24, W12x24, 15x24, 18x24, DW18Lx24, DW16x26, DW20x26, W10x28, 14x28, DW15x28, DW25x28, W14x30, W14x30, 8W x42, DD18Lx42, DW23Bx42, W8x44, W13x46, 10x48, W12x48

Alaabtayadu waxay leeyihiin tayo heer caalami ah.

Waqtiga boostada: Oct-29-2024