Maxay TPMS uga dhigan tahay taayirada baabuurta dhismaha?

TPMS (Nidaamka Dabagalka Cadaadiska Taayirka) ee dhismaha taayirada baabuurta waa nidaam la socda cadaadiska taayirka iyo heerkulka wakhtiga dhabta ah, kaas oo loo isticmaalo in lagu wanaajiyo badbaadada baabuurka, la yareeyo khatarta dhaawaca taayirka, iyo hagaajinta waxtarka shidaalka. TPMS waxay si gaar ah muhiim ugu tahay qalabka culculus iyo baabuurta dhismaha (sida kuwa macdanta qodaya, kuwa qodaya, xamuulka, iwm.) sababtoo ah baabuurtani waxay inta badan ku shaqeeyaan xaalado aad u daran iyo waxqabadka taayirrada ayaa muhiim u ah badbaadada iyo hufnaanta hawlgalka.

Hawlaha iyo doorarka TPMS:

1. La socodka wakhtiga dhabta ah ee cadaadiska taayirka:

-Nidaamka TPMS waxa uu si joogto ah ula socdaa cadaadiska hawada ee taayirka isaga oo isticmaalaya dareemayaal ku rakiban taayir kasta. Haddii cadaadiska hawadu uu ka hooseeyo ama ka sarreeyo qiimaha caadiga ah ee hore loo dejiyey, nidaamku wuxuu soo saari doonaa digniin si uu u xasuusiyo darawalka inuu tallaabo qaado.

- Tani waxay kaa caawinaysaa inaad iska ilaaliso garaacista taayirka iyo xidhashada xad dhaafka ah ee uu keeno cadaadiska taayirka oo hooseeya, ama xakamaynta taayirada oo yaraatay iyo kulaylka taayirka ee uu keeno cadaadiska sare ee taayirka.

2. La socodka wakhtiga dhabta ah ee heerkulka taayirka:

- Cadaadiska hawada ka sokow, TPMS waxay kaloo la socotaa heerkulka taayirka. Marka baabuurta dhismuhu ay shaqaynayaan wakhti dheer ama ay ku socdaan heerkul sarreeya iyo xaaladaha adag ee waddooyinka, taayirku waxay u nugul yihiin kulaylka, kordhinta khatarta ah inay fashilmaan. La socodka heerkulka ayaa ka caawin kara hawl-wadeenada in ay hore u ogaadaan dhibaatooyinka iman kara oo ay ka hortagaan burburka taayirka ama shilalka dabka.

3. Hagaajinta waxtarka shidaalka:

- Cadaadiska taayirrada ee hooseeya wuxuu kordhin doonaa caabbinta taayirrada, taasoo keenaysa korodhka isticmaalka shidaalka. Nidaamka TPMS wuxuu kaa caawin karaa in la hubiyo in taayirka uu had iyo jeer ku jiro qiyaasta cadaadiska ugu fiican, taas oo yaraynaysa isticmaalka shidaalka iyo hagaajinta dhaqaalaha baabuurka.

4. Kordhi nolosha taayirka:

- Iyadoo la ilaalinayo cadaadiska saxda ah ee taayirrada iyo la socodka heerkulka taayirka, TPMS waxay si weyn u yareyn kartaa xirashada taayirka waxayna dheereyn kartaa nolosha taayirrada, taas oo yareyneysa inta jeer ee beddelka taayirada iyo yareynta kharashka dayactirka.

5. Wanaaji badbaadada:

- Marka baabuurta injineeradu ay ka shaqeeyaan meelo adag, dhibaatooyinka taayirada waxay keeni karaan in qalabku uu lumiyo xakamaynta ama xitaa waxay keenaan shilal badbaado oo halis ah. TPMS waxay ogaan kartaa dhibaatooyinka goor hore, waxay ka hortagi kartaa khataraha iman kara, waxayna xaqiijin kartaa badbaadada hawlgalka.

Sida TPMS u shaqeyso:

Nidaamka TPMS wuxuu inta badan ka kooban yahay dareemayaasha lagu rakibay taayirka, qaybta kontoroolka dhexe, iyo qalabka bandhiga. Dareemuhu wuxuu cabbiraa cadaadiska hawada iyo heerkulka ku jira taayirka wuxuuna xogta u gudbiyaa bandhigga darawalka ama nidaamka digniinta isagoo adeegsanaya calaamadaha wireless-ka. Haddii cadaadiska hawadu ama heerkulku uu dhaafo qiyaasta caadiga ah, nidaamku wuxuu soo saari doonaa digniin si uu u oggolaado hawlwadeenku inuu qaado tallaabooyin waqtigeeda ah.

Muhiimadda TPMS ee baabuurta dhismaha:

Baabuurta dhismuhu waxay inta badan ku shaqeeyaan culaysyo culus, dhul qalafsan iyo xaaladaha cimilada adag, cadaadiska taayirka iyo maaraynta heerkulku waa muhiim. Nidaamka TPMS waxa uu ka caawin karaa hawl-wadeenada in ay si fiican ula socdaan heerka taayirka oo ay yareeyaan khatarta wakhtiga hoos u dhaca ee lama filaanka ah, dhaawaca taayirrada ama shilalka badbaadada, gaar ahaan miinooyinka, goobaha dhismaha iyo meelaha kale ee hawlgalka qalabku aad ugu baahan yahay.

Marka la soo koobo, TPMS waxay door muhiim ah ka ciyaartaa maaraynta taayirka baabuurta dhismaha, ka caawinta hagaajinta badbaadada, kor u qaadida waxqabadka iyo dhimista kharashaadka hawlgalka.

Taayirada baabuurta dhismaha iyo cidhifyada taayirrada baabuurta dhismaha ayaa ah qaybo muhiim ah oo ka mid ah baabuurta dhismaha, iyagoo qaadaya culaysyo culus iyo la qabsiga xaaladaha adag ee shaqada.

Waxaan nahay Shiinaha No. 1 naqshadeeye wheel off-road iyo saaraha, iyo sidoo kale khubarada hormoodka ah adduunka ee naqshadeynta qaybaha rim iyo wax soo saarka. Dhammaan alaabooyinka waxaa loo qaabeeyey oo loo soo saaray si waafaqsan heerarka tayada ugu sarreeya, waxaanan leenahay in ka badan 20 sano oo waayo-aragnimo wax soo saarka taayirrada. Waxaan nahay alaab-qeybiyaha asalka ah ee Shiinaha ee noocyada caanka ah sida Volvo, Caterpillar, Liebherr, iyo John Deere.

Shirkadeena waxay si weyn ugu lug leedahay dhinacyada mishiinada dhismaha, muraayadaha macdanta, fargeetada fargeetada, geesaha warshadaha, geesaha beeraha, qaybaha kale ee rim iyo taayirada.

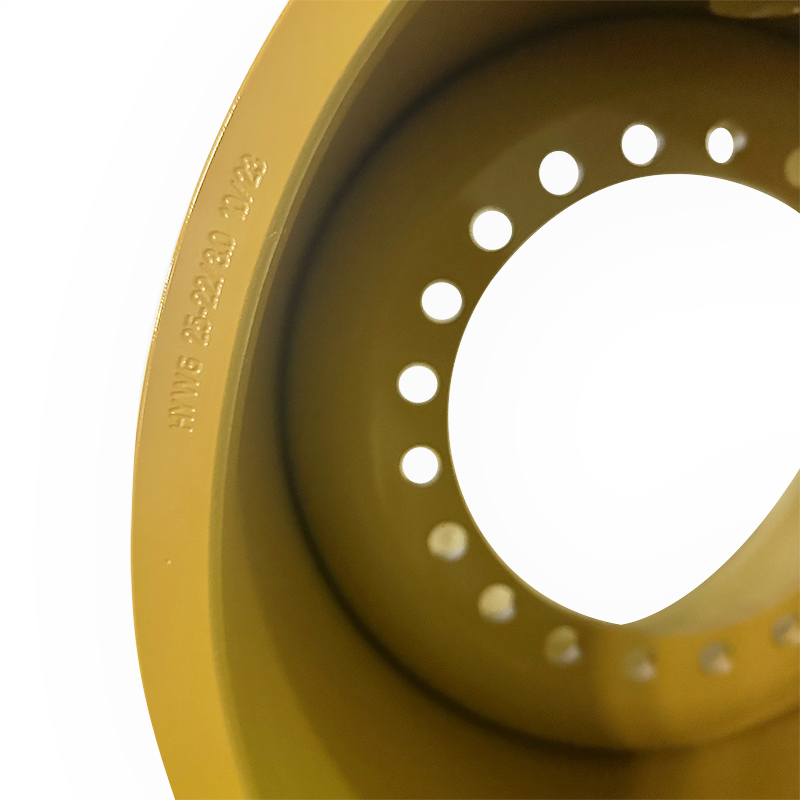

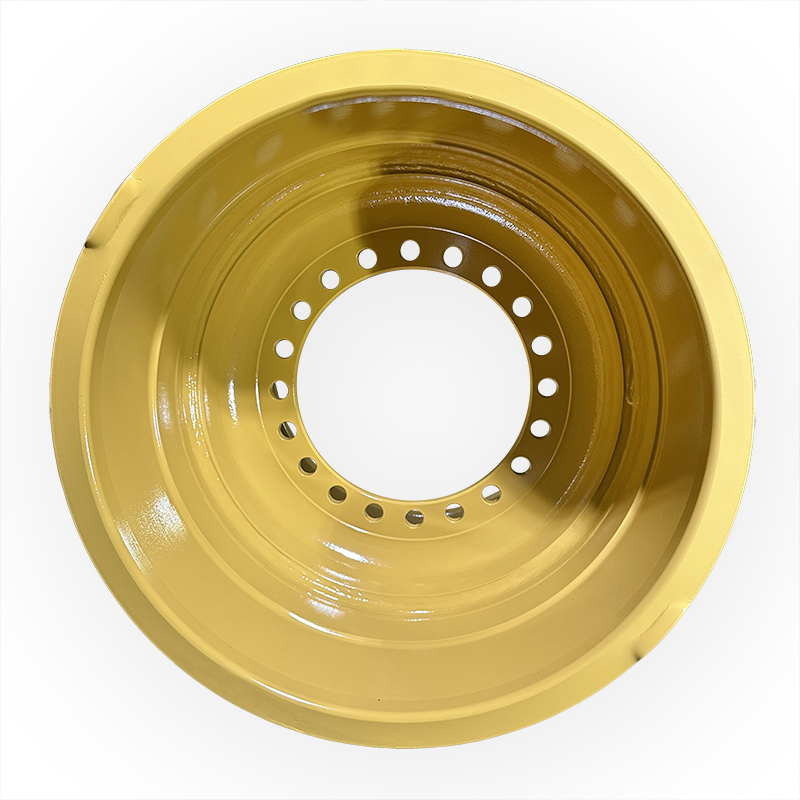

The22.00-25 / 3.0 rimWaxaan siinay Caterpillar si loogu isticmaalo rarida taayirrada baabuurta dhismaha ayaa si wadajir ah u aqoonsaday macaamiisha.

"22.00-25/3.0” waa hab lagu tilmaamo taayirrada iyo cabbirrada xajmiyada, kuwaas oo inta badan loo adeegsado qalabka culculus sida mashiinnada waaweyn ee dhismaha, baabuurta macdanta, xamuulka, iwm.

1.22.00: Waxay muujinaysaa ballaca taayirka ee inji. Tani waxay ka dhigan tahay in ballaca qaybta isdhaafka ee taayirka uu yahay 22 inji.

2. 25: Waxay muujinaysaa dhexroorka cirifka (xarunta giraangiraha), sidoo kale inch. Taas macnaheedu waa in dhexroorka cirifka taayirku ku habboon yahay 25 inji.

3. / 3.0: Qiimahani wuxuu inta badan tilmaamayaa ballaca cirifka injis. 3.0 waxay ka dhigan tahay in ballaca cidhifku yahay 3 inji. Qaybtani waa cabbirka qaab dhismeedka taayirka lagu rakibay cidhifka, iyadoo la hubinayo in taayirka iyo cidhifku iswaafaqi karaan.

Tilmaamahan taayirrada ah iyo cidhifyada ayaa inta badan loo adeegsadaa mashiinnada waaweyn ee dhismaha, sida kuwa xamuulka qaada, cagaf-cagafyada, kuwa macdanta qodaya, kuwa kontaynarrada iwm.

Tilmaamaha ugu muhiimsan:

Awoodda culeyska sarreeya: taayirrada ballaaran iyo cirifka waaweyn waxay u adkeysan karaan culeysyo sare waxayna ku habboon yihiin hawlgallada culus.

Xirashada adag ee iska caabinta: taayirada qeexitaankan waxaa badanaa lagu isticmaalaa deegaan adag waxayna leeyihiin iska caabin xoog leh iyo iska caabin saameyn leh.

Degenaansho wanaagsan: dhexroorka weyn iyo taayirada ballaaran ayaa bixiya aag xiriir wanaagsan waxayna ilaalin karaan xasilloonida dhulka dabacsan ama qallafsan.

Isku darka taayirka iyo cidhifkani wuxuu caadi ahaan bixiyaa taageero lagu kalsoonaan karo oo loogu talagalay baabuurta culculus, hubinta amniga iyo xasiloonida waxqabadka ee xaaladaha adag ee shaqada.

Maxay Taayirada Adag u Isticmaalaan Raalayaasha Taayirrada?

Raalayaasha taayirrada waxay isticmaalaan taayirro adag mararka qaarkood, gaar ahaan si ay ula qabsadaan jawiga shaqada ee adag iyo xaaladaha adag ee shaqada. Sababaha gaarka ah waxaa ka mid ah dhinacyada soo socda:

1. Iska caabin daloolin xooggan

Bey'ad shaqo oo isku dhafan: Raadiyeyaasha taayirrada waxay caadi ahaan ka shaqeeyaan goobaha dhismaha, miinada, goobaha qashinka iyo meelaha kale. Waxaa laga yaabaa in ay jiraan tiro badan oo dhagaxyo af leh, biro, muraayado jaban, iwm oo ku yaal dhulka meelahaas, kuwaas oo si fudud u daloolin kara taayirada caadiga ah ee pneumatic.

Taayirada adagi ma laha dalool gudaha ah: Maadaama taayirada adagi aanay lahayn qaab dhismeed la buufin karo oo ay si buuxda uga buuxaan caag gudaha ah, ma daadan doonaan ama ma dillaaci doonaan sababtoo ah daloolista sida taayirada pneumatic, taas oo aad u yaraynaysa kharashka dayactirka iyo dayactirka ee uu keeno dhaawaca taayirka.

2. Xiro iska caabin iyo nolol adeeg oo dheer

Hawlgalka xoogga badan: Raadiyeyaasha taayirrada waxay inta badan u baahan yihiin qalliin waqti dheer ah iyo kuwo xooggan, taayirrada waxaa la marsiin doonaa is jiid jiid badan iyo xirmo badan. Taayirada adag waxay leeyihiin iska caabin ka sarreeya taayirada pneumatic-ka caadiga ah sababtoo ah cufnaanta alaabta sare, sidaas darteed waxay leeyihiin nolol adeeg oo dheer oo ku jira xaalado adag.

3. Dayactir la'aan

Looma baahna sicir-bararka ama dayactirka joogtada ah: Taayirada adag waxay baabi'iyaan dhibaatada sicir-bararka taayirada, ogaanshaha cadaadiska taayirka iyo hagaajinta. Xaaladaha u baahan hawlgal joogto ah, isticmaalka taayirada adag waxay si weyn u dhimi kartaa wakhtiga dhimista ee ay sababaan dhibaatooyinka taayirka, taas oo kor u qaadeysa waxtarka wax soo saarka.

4. Awood culus oo culus

Waxay u adkaysataa culaysyada waaweyn: Raadiyeyaasha taayirrada waxay inta badan u baahan yihiin inay qaadaan oo qaadaan alaab culus. Taayirada adagi waxay leeyihiin awood rarka qaadis ka xoog badan taayirada pneumatic-ka oo si sahal ah uma qalloocaan ama u dhaawacmaan culayska xad dhaafka ah awgeed. Waxay si gaar ah ugu habboon yihiin waqtiyada ay walxaha culus u baahan yihiin in si joogto ah loo raro.

5. Deganaanshiyo wanaagsan

Waxqabadka ka-hortagga seismic-ka xooggan: Taayirada adag waxay leeyihiin qaab-dhismeed adag iyo xoog labis ah. Marka la qaadayo walxaha culculus, ma yeelan doonaan qallooc weyn oo laastikada ah sida taayirada pneumatic, si ay u bixiyaan khibrad wadista oo xasilloon, gaar ahaan dhulka qallafsan.

6. Ku habboon hawlgallada xawaaraha hooseeya iyo kuwa fogaanta gaaban

Isticmaalka taayirada adag ee lagu rakibo taayirrada goobaha shaqada ee aadka u daran waxay si weyn u wanaajin kartaa isku halaynta, adkeysiga iyo badbaadada, waxayna yaraynaysaa kharashka dayactirka taayirka. Taayirada adag ayaa ah doorasho ku habboon oo ku hoos jirta khatar sare, culays badan, iyo xaalado shaqo oo xawaare hooseeya.

Kuwa soo socda waa cabbirrada kala duwan ee rims ee shirkadeena ay u soo saari karto meelo kala duwan:

Cabbirrada mashiinnada injineernimada: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 10.00-25, 11.25-25, 12.00-25, 20-5, 13.00 17.00-25, 19.50-25, 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 13.00-3.

Cabbirrada macdanta: 22.00-25, 24.00-25, 25.00-25, 36.00-25, 24.00-29, 25.00-29, 27.00-29, 28.00-33, 16.00-.30-34,16 19.50-49, 24.00-51, 40.00-51, 29.00-57, 32.00-57, 41.00-63, 44.00-63,

Cabbirrada Forklift waa: 3.00-8, 4.33-8, 4.00-9, 6.00-9, 5.00-10, 6.50-10, 5.00-12, 8.00-12, 4.50-15, 5.50-15, 5,00-10 8.00-15, 9.75-15, 11.00-15, 11.25-25, 13.00-25, 13.00-33,

Cabbirrada baabuurta warshadaha waa: 7.00-20, 7.50-20, 8.50-20, 10.00-20, 14.00-20, 10.00-24, 7.00x12, 7.00x15, 14x25, 8.25x16.5x. 13x15.5, 9x15.3, 9x18, 11x18, 13x24, 14x24, DW14x24, DW15x24, DW16x26, DW25x26, W14x28 , DW15x28, DW25x2

Cabbirrada mishiinada beeraha waa: 5.00x16, 5.5x16, 6.00-16, 9x15.3, 8LBx15, 10LBx15, 13x15.5, 8.25x16.5, 9.75x16.5, 9.75x16.5, 9x18, 18x18, Wx18, W18,18Wx18,W18,18WX18,18WX 5.50x20, W7x20, W11x20, W10x24, W12x24, 15x24, 18x24, DW18Lx24, DW16x26, DW20x26, W10x28, 14x28, DW15x54x10 DW16x34, W10x38 , DW16x38, W8x42, DD18Lx42, DW23Bx42, W8x44, W13x46, 10x48, W12x48

Alaabtayadu waxay leeyihiin tayada adduunka.

Waqtiga boostada: Oct-10-2024